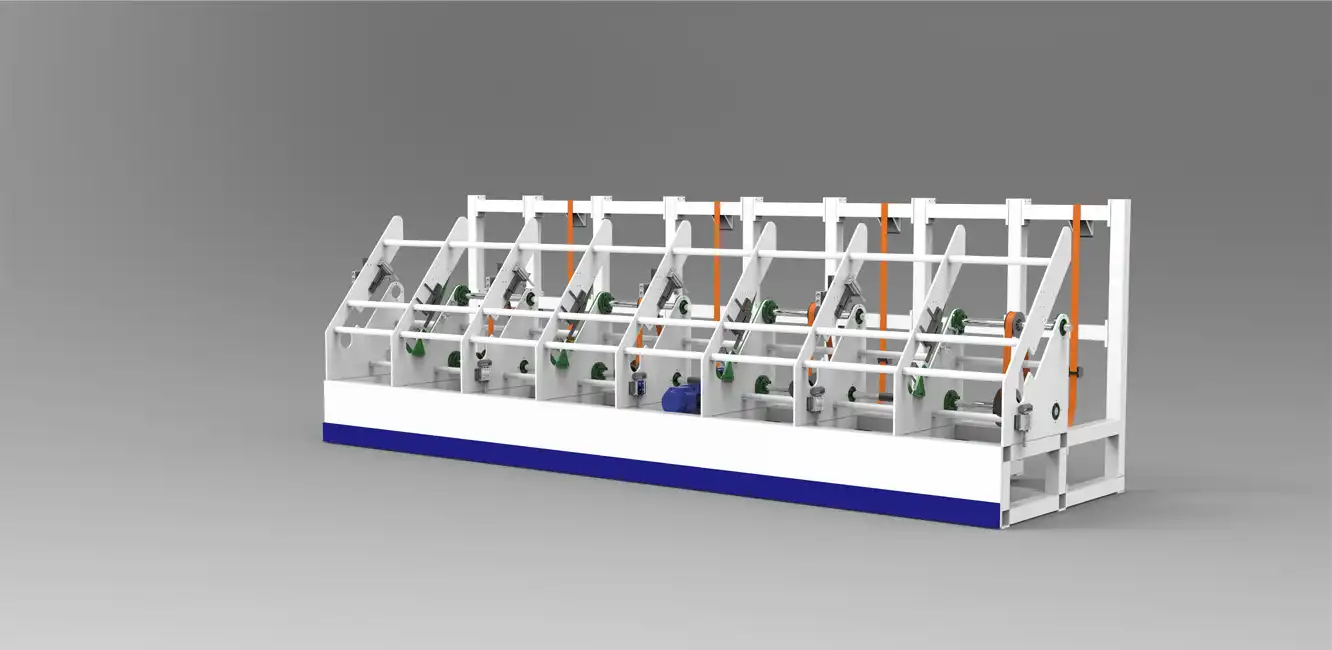

Bigger loading capacity: maximum two bundles of pipes can be loaded at one time;Accurate loading capability: pneumatic device and stoke cylinder limit ensure the loading accuracy;Smaller pipe loading capability: multi-clapboard design enables to load small pipe (below D10mm);High-efficient loading capability: 4+ pipe buffer area design with monitoring device enables cutting and loading simultaneously

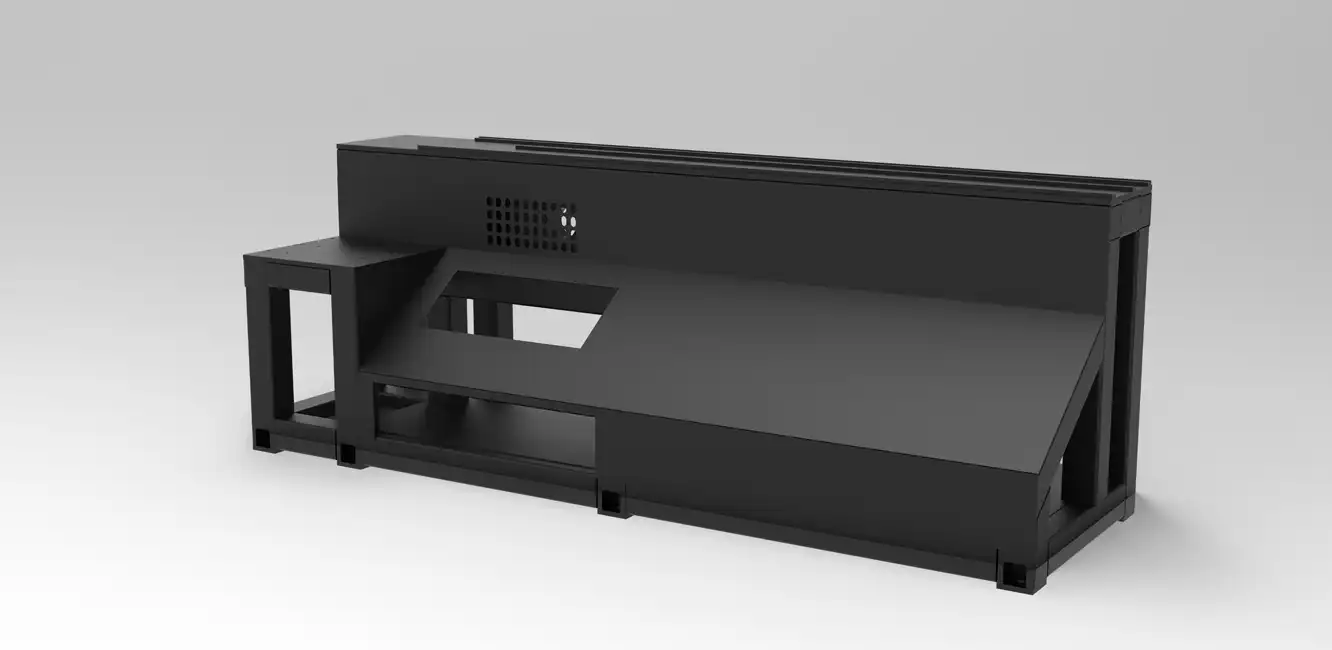

Stable: High strength tube welded machine bed; Convenient:equipped with inclined unloading table;Environmental protection: equipped with large size exhaust adsorption area; Functional: equipped with scrap metal collecting system

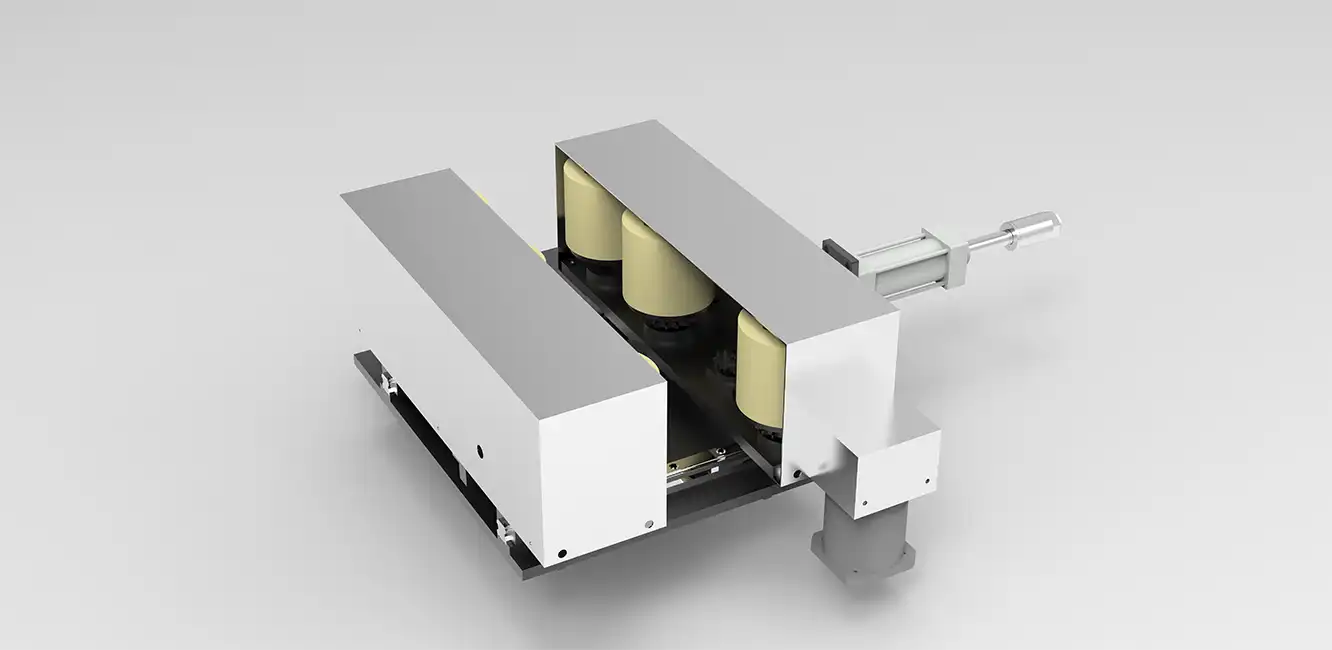

Smart :two detector switches monitor the real-time position of pipe; Accuracy: three synchronized wheels make sure the feeding accuracy; Multi-rubber wheel clamping: feeding fast without hurt the pipe surface; Adjustable clamping strength & stroke: clamping pipe tightly without deformation.

Stable: equipped with integrated base for chuck; Convenient:equipped with adjustable jaws for the chuck; High-speed: equipped with high-speed chuck(150rpm+); Accuracy: two-layer chuck design, better cutting accuracy

| Model | K90 | T120 | T160 | T245 | T360 | T160max | T245max | T360max | T500max |

| Power | 1.5-3kw | 1.5-3kw | 1.5-3kw | 1.5-6kw | 3-12kw | 1.5-3kw | 1.5-6kw | 3-12kw | 6-20kw |

| Y axis feeding way | Pulling | Feeding | Feeding | Feeding | Feeding | Feeding | Feeding | Feeding | Feeding |

| Repositioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Cutting accuracy | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| Number of chucks | 1 | 2 | 2 | 2 | 2 | 3+1 | 3+1 | 3+1 | 3+1 |

| Acceleration | 2G | 2G | 1.2G | 1G | 0.8G | 0.4G | 1G | 0.8G | 0.4G |

| Diameter range of pipe | 8-90mm | 10-120mm | 10-160mm | 20-245mm | 40-360mm | 10-160mm | 20-245mm | 40-360mm | 50-500mm |